News

Thank You!

Thank you for visiting us during ProMat 2025 in Chicago!

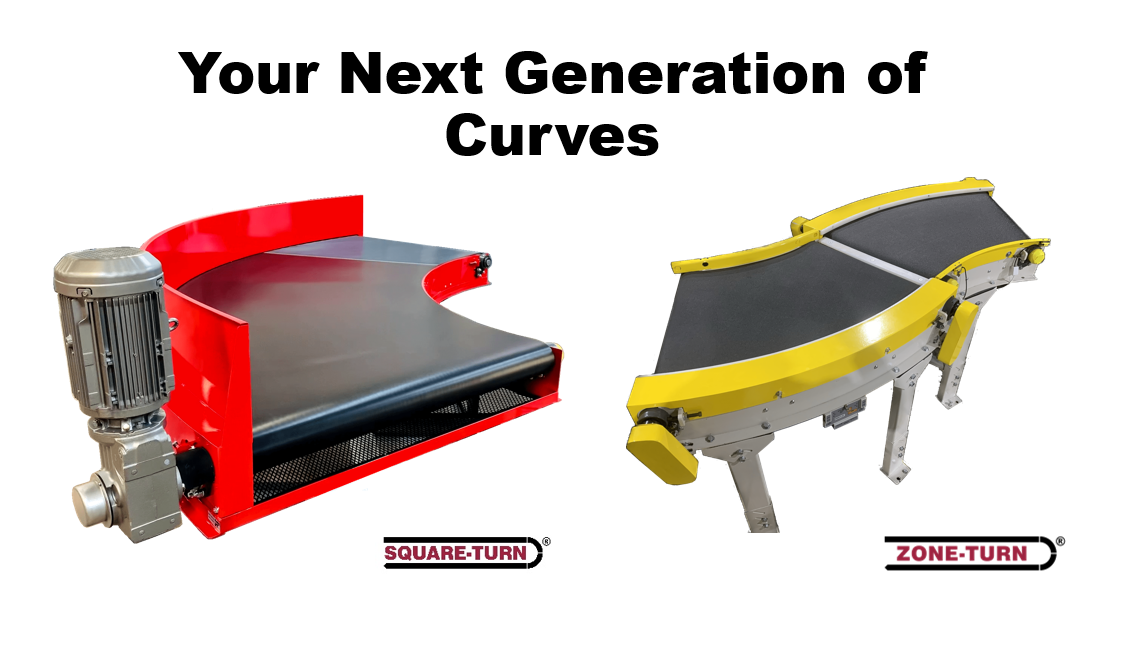

We saw great interest in our Flow-Lift vertical conveyor, SKR Straight Knife Roll Conveyor, Flow-Merge FMSB with strip belts, and our Square-Turn belt curve. Please check here for more information click here or reach out to us by email.

New Product

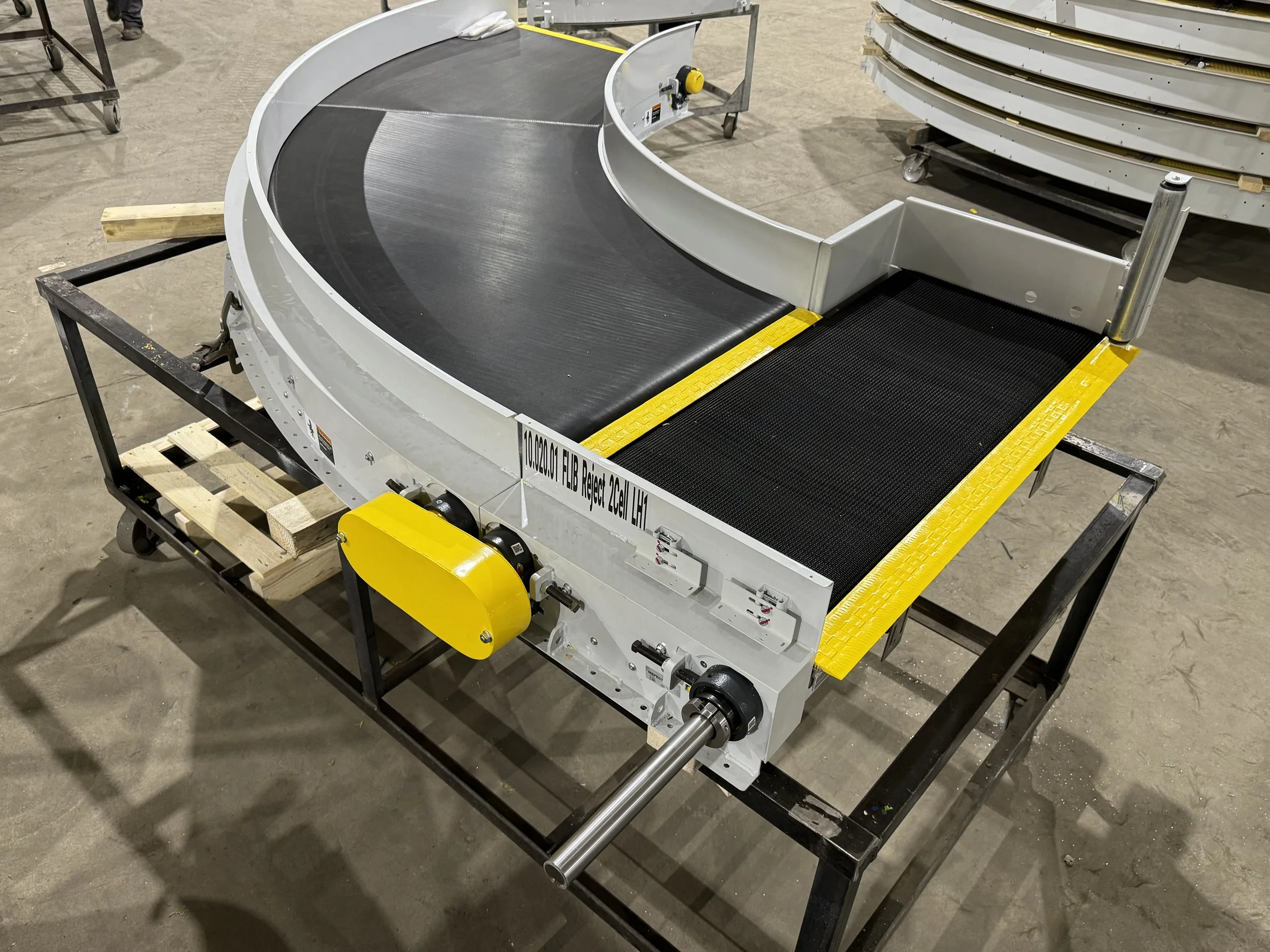

Check out our all new Flow-Merge FMFW, this merge conveyor might be the solution you have been looking for. This full-width belt merge is designed with reliable operation and simple maintenance in mind. It’s unique benefits include:

Laced Belting - Laced belts allow for a quick and easy belt replacement. Other maintenance, such as pully replacements can be completed with minimum downtime

Small Footprint - FMFW merges do not require special belt tracking stations, minimizing the required footprint

Reliable Operation - FMFW belts don’t require as much tension as other merge belts, the short and symmetric design improves belt tracking. Tracking adjustments can easily be made with snub rollers

Minority owned and operated Recognition

Flow-Turn is proud to announce that we have been officially certified as a Minority-Owned Business by the New York/New Jersey Minority Supplier Development Council. This certification underscores our commitment to diversity and excellence in the manufacturing industry. It also opens new opportunities for us to collaborate with organizations that prioritize supplier diversity, enabling us to contribute to more inclusive and innovative supply chains. As we continue to grow, this certification reaffirms our dedication to fostering a diverse workforce and delivering high-quality, custom-engineered solutions that need the unique needs of our clients.

Our

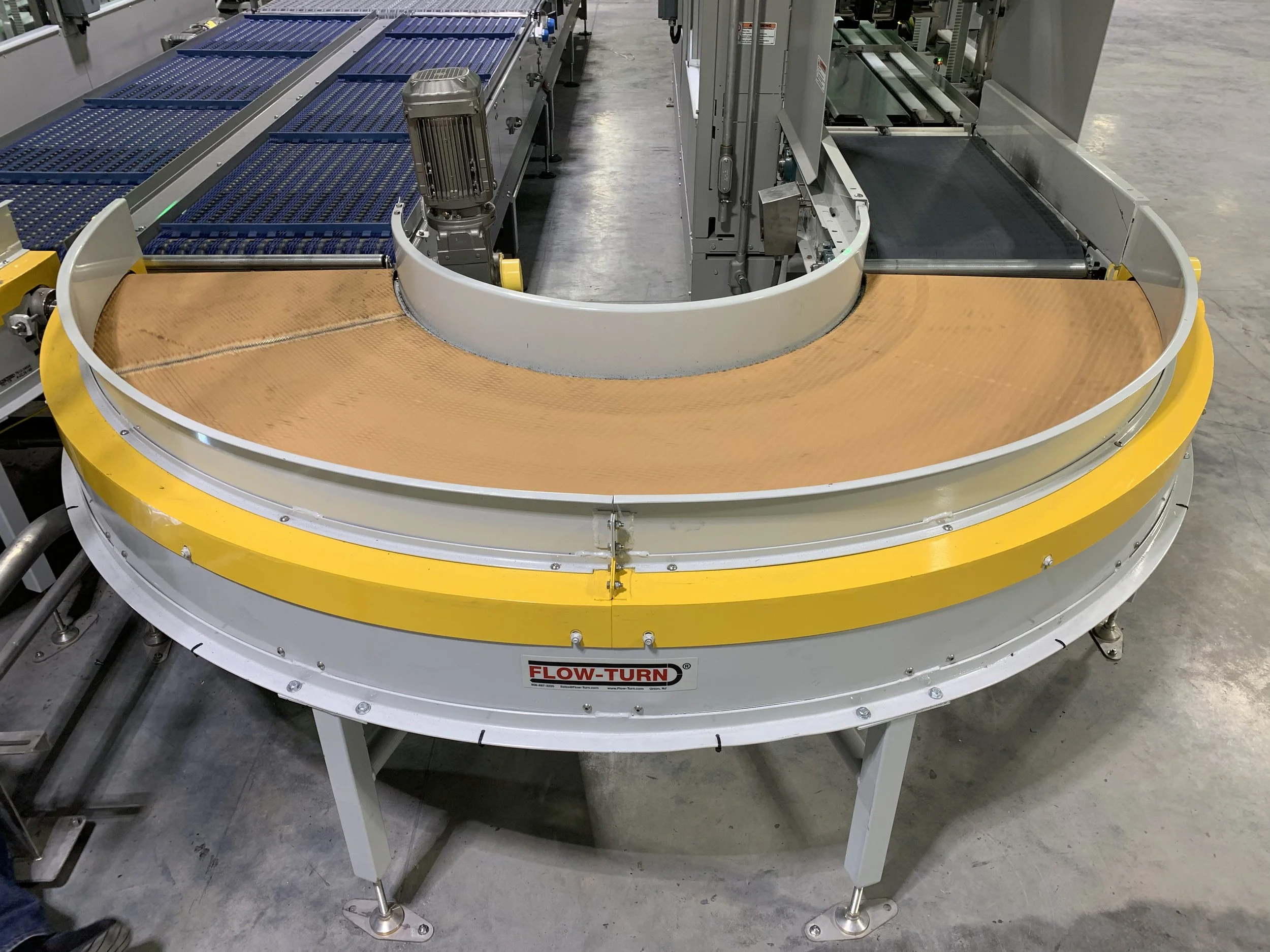

Portfolio

Can we help you create Your Vision?

Connect with our highly skilled sales team to discover how Flow-Turn can bring your project to life. Our engineers excel at streamlining efficiency across all our product lines. Let’s work together to turn your ideas into reality.